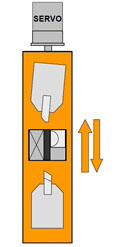

Programmable Servo Central Slide

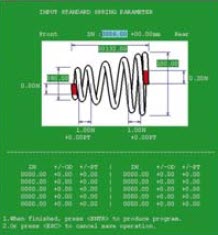

Graphic Programming

Standard 6 Axes

- 1 Feed

- 1 O.D.

- 2 Cutter/Vertical Pitch

- 1 Horizontal Pitch

- 1 Mandrel Up/Down

Optional Accessories

- (S) Safety Guard

- (A) Torsion Attachment

- (SDR/L) Servo Pretention Device of Compression Spring (Right/Left Coiling)

- (L) Long Spring Guide

- (WF3) Wifi Operation Monitoring with VNC Function

- (APS) Air Pressure Switch

- (WDD) Wire End Detection

- (STR) Wire Stripper (for copper wire)

- (SLG) Spring Length Gage

- (OSG) Optical Spring Gage

- (HR) Wire Pay Off System

- (FR) High Speed Wire Pay Off System

| Model | Wire Dia. | Max. O.D. | Production Rate | Total Power | Dimension (LxWxH) | Weight |

|---|---|---|---|---|---|---|

| HTC 28CP | 0.8mm – 3.0mm (.031″ – .118″) |

45mm (1.77″) |

Max 250 pcs/min | 15kw | 152 x 100 x 182cm (60″ x 39″ x 72″) |

1100 KGS (2400 LBS) |

OPTIMUM MECHANICAL DESIGN

- The Central Slide (i.e. the cutter, pitch slides and mandrel all together) will move to the correct position automatically according to the program while

O. D. is changed during production, which provides setup convenience and strengthens cutter structure. - Cam-less operation provides quick and easy setup.

- Rotating cutoff and straight cutoff capability are both standard features for more flexible application.

- Mandrel in-out movement is programmable which provides setup flexibility.

- Automatic oil pump insures equal lubrication for slides.

- Roller pressure gage insures repeatable feed roller pressure while material changed.

- Heat exchanger on the electrical cabinet keeps controllers clean and cool.

- Optional torsion attachment is available.

CNC CONTROL SYSTEM AND EXCEPTIONAL SOFTWARE DESIGN

- 6 servo motors, industrial computer controlled insures reliable control.

- Graphic and easy to use software simplifies programming.

- A micro pulse hand wheel is used for easy setup and programming.

- The computer system stops machine if a programming error exceeds machine setup capability.

- On-screen diagnostics shows alarm status and corrective action required. Standard spring shapes are pre-programmed in computer CPU for easy setup.

- O.D. control is standard feature.

- Touchscreen control interface for easy operation.

- Programmable air valves provide flexible pneumatic application.

- Safety sensor and position sensor included.

- USB data access interface, convenient for program backup, production management and system rescue.