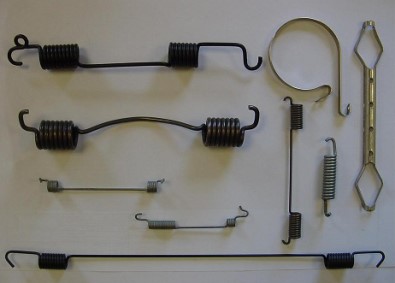

TBE wire forming machinery provides leading edge technology for high-speed automated production of complex wire forms and springs, eliminating the need for costly secondary operations. Applications include automotive components (brake springs, seating, lumbar, retainers, rods, trim wires etc.), medical, bedding forms and springs, lawn equipment, and construction (wall ties, anchors, concrete support wires) etc.

Available Features Include:

- Touch Screen HMI

- AB Controls & Motors

- High Speed Servo Feed Systems

- Integrated Rotary Wire Straightener

- Multi-Axes Forming & Positioning

- Servo Forming & Winding Heads

- Mandrel Coil Winding Heads

- Rotating Wire

- Auto Component Indexing for Multi-Plane Forming

- Accurate Transfer Systems

- Modular Quick Change Tooling

- Press Stations to 150 Tons

Automated Processes May Include:

- Integrated Rotary Straightening

- Welding

- Heading

- Threading

- Chamfering

- Press Operations – Up to 150T

- Trimming

- Assembly

- Hooking & Looping

- Piercing

- Packaging & Lot Control

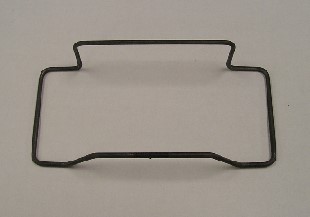

3-D Wire Forming and Welding

TBE Multibend Wire Forming Machines utilize features such as multi-axes servo control, wire rotation, component indexing, plus fast and accurate transfer systems which allow total automation of complicated wire parts for 3-D, 2-D, or assembly applications. Welding of 2-D or 3-D components is ideally suited to the flexible TBE Multibend platform. TBE perfected transfer systems simplify the process of moving finished forms to welding stations (plus, in the case of spring steel, into the required annealing stations) and additional secondary operations.

Special Spring Automation

TBE specializes in automation of springs and wire forms which normally require costly secondary operations. Servo controlled mandrel winding heads provide high speed, excellent positioning, and excellent diameter control. This translates into world class Cpk capability for load and dimensional requirements. By incorporating their unique transfer technology, TBE automates such spring making processes as trimming short hooks, chamfering ends, flattening, twisting, & crimping.